Please note that this press has a rounded end and is only appropriate for our pre-shaped veneer or very small projects. Cannot be used with uncut / natural / rectangular veneer.

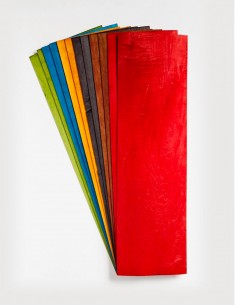

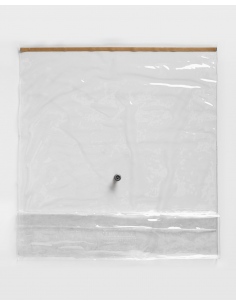

Thin Air Press Bag 14 x 47"When you already have all the elements included in our Thin Air press kits, get multiples of this size bag for production work, as a replacement or addition to your other sizes. Useful for schools and groups and garage builders who require multiple bags so that more than one project can be made during the same gluing session. This size press is specifically designed for our pre-shaped veneer sets and molds. Originally offered in our complete board building kits, it has a rounded end and is small and easy to use for all your pre-shaped builds.

|

FAQIs this reusable, and for how many times? The kits are designed to be used many many times. With a little care and maintenance, the TAP Kits will last for years. Will the glue stick to the bag? One board at a time. You are limited by how fast your glue dries. Once you start spreading water-based glue on the veneer sheets, you have about 7-10 minutes to get them pressed before the glue dries. Do the valves leak? While many people assume air is leaking back through the valve, they are made of cast rubber and almost never leak. The most common problem with slow leakage is the open-end seal tape. If the seal is not properly closed up (check both sides) you will lose vacuum. If the top cap of the valve is not compromised with dust and debris, the valve will not leak. Do you refund my veneer if the pressing doesn't work? Sorry, we don't offer reimbursement in these cases. Whats a Dry Run and why should I do that? It means to press your project in the TAP bag, without putting any glue on the veneer sheets. Stack the dry sheets of veneer over the mold, seal them into the press with the breather netting in place, and pump the air out. Check for 10 minutes to make sure the TAP bag is not leaking. This will help you become familiar with the process before you commit glue to your veneer sheets. |