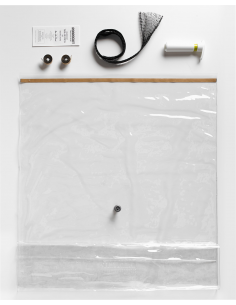

Thin Air Press Kit 26x28"The Thin Air Press Kit 26 x 28'' (66 cm x 71 cm) is a simple and inexpensive innovation for pressing multiple projects. The kit can be re-used many times, and other sizes are available to suit your project. This size of press is ideal for small projects, such as jewellery, small woodworking projects, marquetry and more. Easy to use, no power required.

|

FAQIs this reusable, and for how many times? The kits are designed to be used many many times. With a little care and maintenance, the TAP Kits will last for years. Will the glue stick to the bag? If the TAP Bag gets a hole in it, can I fix it? Clear 2 packing tape seals up any suspected punctures. Use a length of the butyl tape to fix any side seam gaps or splits. See instructions for more info. Do the valves leak? While many people assume air is leaking back through the valve, they are made of cast rubber and almost never leak. The most common problem with slow leakage is the open-end seal tape. If the seal is not properly closed up (check both sides) you will lose vacuum. If the top cap of the valve is not compromised with dust and debris, the valve will not leak. Do you refund my veneer if the pressing doesn't work? Sorry, we don't offer reimbursement for these types of problems. Whats a Dry Run and why should I do that? It means to press your project in the TAP bag, without putting any glue on the veneer sheets. Stack the dry sheets of veneer over the mold, seal them into the press with the breather netting in place, and pump the air out. Check for 10 minutes to make sure the TAP bag is not leaking. This will help you become familiar with the process before you commit glue to your veneer sheets. |

Thin Air Press Kit 26x28"

In Stock

€104.00

Tax included

A simple and effective way to vacuum-laminate layers of veneer for woodworking projects.

Description

Product Details

Reviews

No reviews

Customer reviews

Reviews about this product

-

Everything is perfect. Works very well for my application.

-

Very good product, used for violin making, for laminated archtops or ribs. The only drawback is that the sealant may not be the most practical, especially for the opening, it's a bit of a handful, but it works perfectly. (Translated review)

Customers who bought this product also bought:

€21.00

For marquetry, jewellery and many other smaller laminating projects, this generous box of offcuts will give you a bundle of material to work with.

€1.85

Maple veneer scrap sheets for recycling into new projects.

€28.00

Titebond III, a high quality water-based and waterproof glue.

€13.00

This is a cheese-grater on steroids! This tool sands off wood and shapes foam too.The Surform Scraper looks innocent but does an awesome job in a hurry.

€7.00

2 rolls of sealing tape. Use this to replace worn out tape after your original seal and replacements are used up.

€68.50

From €46.50 By 20

Maple makes the strongest skateboards in the world!

€3.44

Maple veneer scrap sheets for recycling into new projects.

€37.00

From €22.00 By 20

Maple makes the strongest skateboards in the world!

€189.00

A simple and effective way to vacuum-laminate layers of veneer for large woodworking projects.